Product lines

Spray Congealing (Spray Chilling)

Mini Extruder EHM-5

Friability Tester LFR-2

Rotary Drum

Centrifugal Mill

Gas Scrubber

Mixers

Peristaltic Pump BP-1

CMT Atomizers

The ultimate spray drying solution.

Spray drying is applied to any pumpable product such as emulsions, pastes, solutions and suspensions.

Labmaq do Brasil manufactures and supplies spray dryers of different scales according to the demand and needs of its customers, with its own projects and innovative designs. They are compact, versatile, robust and offer excellent results, performance and powders with high performance in spray drying. In addition, they cover a wide range of applications in the pharmaceutical, food and beverage, agriculture, chemical, polymer, ceramics, cosmetics and aroma industries, among others.

Equipment with capacity above 10L/h or with specific layout, safety, classified area requirements, etc. they are custom-made according to your needs, therefore, contact our technical-commercial sector.

SD 10.0

The Spray Dryer SD 10.0 is a device capable of fast drying, up to 10.0L/h (water reference), of aqueous products. Its compact module has been carefully designed to meet both pilot-scale production demands and industrial-scale production needs, ensuring versatility and efficiency in the drying process.

It has a command and control structure built in carbon steel with anti-corrosion treatment and electrostatic powder painting. Separately, it has a chamber module with skid with wheels to facilitate movement and cleaning. The parts that come into contact with the materials involved in drying are all stainless steel or boron silicate glass. Its great differential is a control system and variation of the air flow with a real-time measurement system using a Pitot tube.

In addition to being robust and compact, the SD 10.0 is easy to operate. The atomization can be monitored by a window located in the inspection door of the drying chamber, made of stainless steel with internal and external polishing and GMP finish, thermally insulated, equipped with LED lighting. Cyclone made of polished stainless steel also with GMP finish. The equipment has TC nipple type connections, facilitating the assembly, sealing and asepsis of the parts. The chamber also has a pneumatic vibrator system that, when working, results in the release of the product powder that can be adhered to the wall and improves the process yield, being activated directly on the HMI screen.

SAFETY

It has a dedicated panel for control and automation with PLC system, HMI touch screen and USB output for data capture, command, process reporting and graphics. It is equipped with an emergency button for greater security and protection of the system, in addition to alarms and interlocks in cases of high temperature or low flow.

The equipment comes with a complete Operation Manual and SOP suggestion (Standard Operating Procedure). We also provide a list of spare parts and access to a video tutorial with step-by-step instructions on how to assemble and operate your equipment. By becoming a Labmaq partner, you will also have exclusive access to our database of scientific articles in which you have hundreds of articles and literature published with our equipment.

| SD 10.0 | |

| Capacity | Up to 10.0L/h (ref. water) |

| Atomization | Double Fluid (Pneumatic) - Top Spray |

| N° of nozzles included | 2 |

| Max. Energy Consumption | 34,000W |

| Voltage | 380V |

| Compressed air consumption | Up to 150L/min |

| Recommended compressed air pressure | 8 to 10 bar |

| Maximum operating temperature | 250°C |

| Maximum feed flow | 10.0L/h (ref. water) |

| Dimensions in mm (LxHxW) | 3,875 x 3,300 x 2,030 |

PHARMACEUTICAL STANDARD

Labmaq do Brasil offers pharmaceutical standard spray dryers in its portfolio. Please see the special conditions for qualifications that meet ANVISA's GMP's - RDC 17 (Qualification of Installation, Project, Operation and Performance - IQ, QP, QO, QD).

Customizable features for pharmaceuticals:

● Command and control structure and AISI 304 or 316L stainless steel finishes.

● 3-stage drying air filtration system (HEPA filter).

● Air supply system after HEPA filter in AISI 316L stainless steel.

● Automation that meets CFR 21 - Part 11 (Hardware and Software).

● Qualifications that meet ANVISA's GMP's - RDC 17 (Qualification of Installation, Project, Operation and Performance).

Customizable Filtration System

Filtration systems are bag filter systems for connection to the dust separator cyclone outlet. They are designed for different flows and materials, aiming to meet the most diverse applications.

They consist of an AISI 304 stainless steel structure with casters to facilitate movement and bag filters to retain particles of a wide range of sizes. These sleeves can be made of polypropylene, polyethylene, polyester, among others, and have openings in their fabric to retain particles from 1 micron, depending on the application.

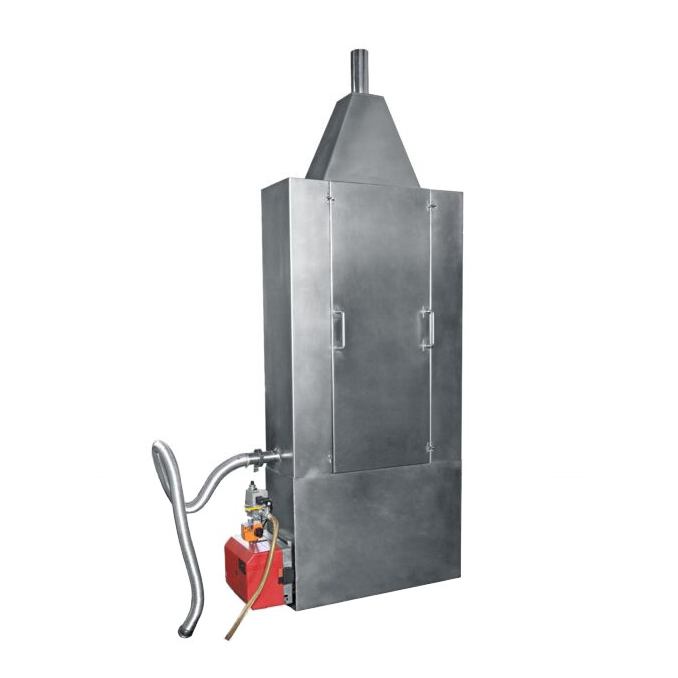

Indirect Air Heating System

For pilot/industrial scale Spray Dryers that use gas burners, we offer the solution for products that cannot come into direct contact with flue gases.

Generally, the system is required for pharmaceutical formulas, food and export products, among others.

This accessory is designed and manufactured according to your drying plant and calculated to be energy efficient, meeting the desired drying temperature.

Model comparison table

Operation

Spray drying techniques start with the preparation of the liquid sample, and may include several processes such as extraction, concentration, mixing, homogenization, formulation, additives, among others. It is important to highlight that the solids content is what will determine the amount of liquid that is being evaporated and the amount of powder that will result from drying. Therefore, concentrating your product before feeding it into the equipment can save you money and increase productivity.

Afterward, the product can be fed into the system, which is done from an atomization system that is formed by a nozzle or a rotary atomizer. This system transforms the liquid solution or suspension into thousands or even millions of droplets that come into contact with the heated drying gas, initiating evaporation and forming the solid product. This technique is based on increasing the contact surface to increase mass and thermal exchange efficiency. This same drying gas, which is normally ambient air, transports these particles out of the chamber to the cyclone, which separates the gas with the evaporated moisture from the powder particles. Thus, dust is collected in the lower part of the cyclone and in the upper part there is the air/gas exit from the process.

Thus, this process includes two large groups of variables for optimization and development: the formulation group and the drying process group. The first refers to formulation variations such as pre-preparation, composition (such as sugar, fat and protein levels), solids content, viscosity, stability, temperature sensitivity and additives. Additives can have different objectives, such as microencapsulation, which can provide the final powder product with numerous advantages, such as wall protection against oxidation and light, masking of undesirable flavors and controlled release of the active ingredients of interest.The second refers to the process variables. Among them are the type and size of the atomization system, flow and drying gas/air inlet, product feed flow and temperature of the drying gas. They all influence the appearance and final result of the powdered product.

Advantages

The spray drying method offers some advantages over other drying methods, including:

1 - High Productivity, when compared to costs of other similar drying methods.

2 – A wide range of applications, which can be applied to practically every type of product, unlike other drying methods that can be more restricted.

3 - Easy process scalability, with availability of equipment on laboratory, pilot and industrial scales.

4 - High quality and durable powder product, as through R&D parameters and formulations can be fine-tuned, enhancing the qualities of the in natura product and increasing the shelf life of the products.

Microencapsulation by Spray Drying

Microencapsulation is the inclusion of an active substance in a solid polymer matrix forming a microsphere. It has applications in products such as essential oils, herbicides, insecticides, parasiticides, biological traps, bio pesticides, drugs, food products, mineral supplements, aromas, fragrances, and natural additives, among others.

Microencapsulation can be performed concomitantly with spray drying and preserves the active substance from the degrading conditions, prevents nutritional losses, inhibits reactions with other agents, masks color, odor and flavor, increases shelf life, reduces the risk of toxicity in the product handling and avoids contamination.

There are thousands of different additives and the first step is to assess the purity and application requirements of the final product. There are additives for the agricultural, food, pharmaceutical, cosmetic sectors. Depending on your final product, additives need to be restricted to the correct sector. The second step is to define the scope of microencapsulation and which characteristic you want the wall material to add to your final product?

Our R&D team has decades of experience with microencapsulation and we can help you develop your product. In addition, Labmaq spray dryers have all the necessary tools for microencapsulation and nebulization drying, designed in detail to be used in research in development laboratories, as well as in production and manufacturing.